MOLSIEVE DESIGNS LTD.

Featured Products

Highest quality standards are achieved through the implementations of latest technology, decades of experience and everlasting moral values , which have helped us to retain our customers as well as multiply them.

Welcome to MOLSIEVE DESIGNS LTD.

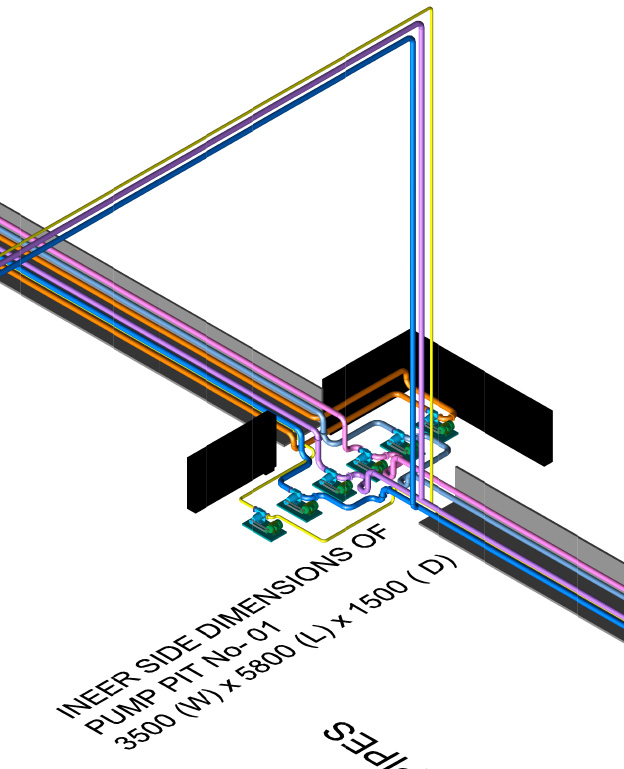

Vacuum Pumping Systems

In order to obtain void-free epoxy castings with low partial discharge and good du-electric strength suitable for use at high voltage it is necessary, among other things, to mix the resin & pre-dried filler well, to de-aerate it by vacuum and finally to pour it, also in vacuum.

The mixing chamber with circular cone-shaped bottom is heated with an oil jacket, the temperature being measured and controlled continuously. The temperature of the wall is hence uniform. A stirrer with baffle rotating at the correct speed which gives shearing action causes thorough resin filler mixing. The agitation exposes all the mix to vacuum& thus degassing is thorough. The mixing paddle drive is with 3 phase motor & reduction gear. The shaft seal is robust rotary seal with tapered roller bearings. The pouring valve is made of P.T.F.E. (Teflon) & this makes cleaning easy. Trap is used to very effective stop abrasive filler particles from entering & ruining the vacuum pump.

Our Vision

* To embrace new technologies and methods. * To give unsurpassed products and services to the clients. * To constantly look for improvement and changes.